I find this very useful in understanding the importance of this upgrade from the standard differential

One-way bearings are still considered the "mystery" option in racing. We see them listed on the "Options" pages in kit instruction manuals, but how do they work? What do they do? And how will they affect your car's performance? There are several types of one-ways, and they can be installed in a variety of locations on the car. In this article, I explore the types of one-ways available and explain how they affect a car when it's racing.

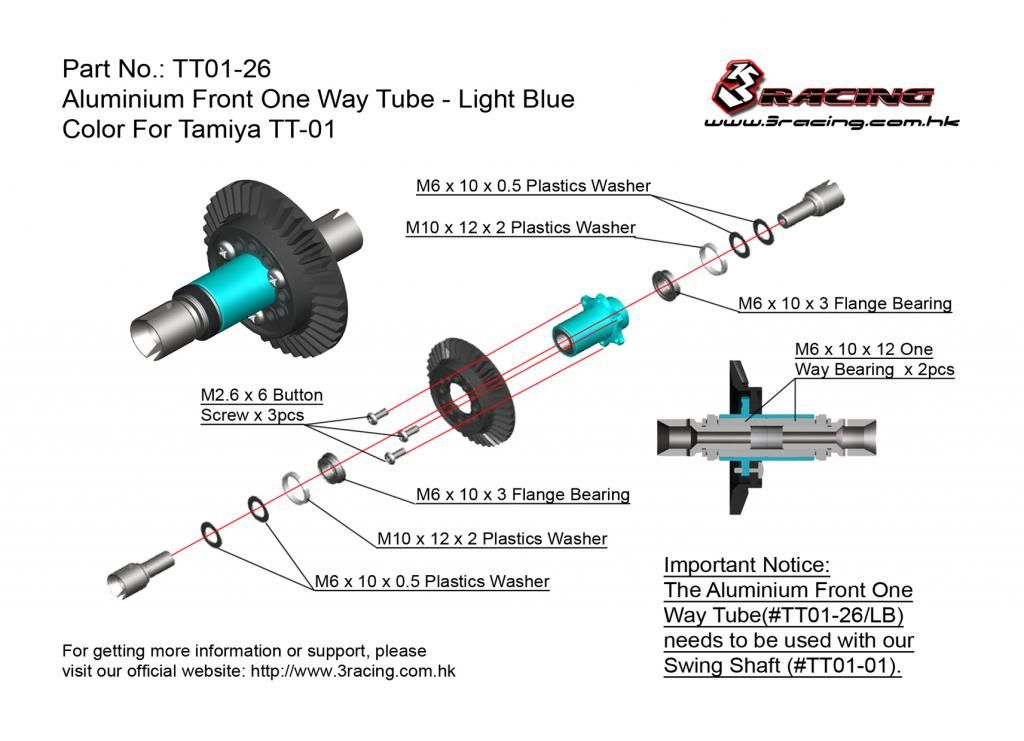

INSIDE A ONE-WAY

As the name implies, a one-way bearing functions in only one way: it rides on various types of shaft that pass through its center, and the shaft, or bearing, rotates freely in one direction but locks in the other direction. A one-way bearing comprises numerous roller, or needle, bearings inside a metal case. The shape of the race allows the bearings to rotate in one direction but not the other (hence the term "one-way"). These bearings are installed so that they "lock up" to drive the shaft they're on when powered. When no drive force is being applied, the bearings are released from their locked position and will spin freely. The bearings can be in several places in the drive train, and they may be found in both nitro and electric cars.

* Front-differential one-way. This unit replaces the front differential. The replacement unit usually incorporates two one-way bearings�one for each outdrive. This setup allows the wheels to spin independently of one another, but it doesn't allow "true" differential action in a corner; the outside wheel will simply freewheel.

* Center layshaft one-way. These units are used on both nitro and electric vehicles. On an electric car, you'll find the one-way bearing on the layshaft (the shaft to which the spur gear is attached). The one-way bearing transfers power to the front diff under acceleration but allows it and the front belt to "freewheel" while decelerating or braking. Unlike a one-way "diff," a center one-way allows front differential action. Since most nitro-powered cars have three belts, they also have two layshafts; the one-way bearing is usually installed on the layshaft that drives the front end.

* Clicker one-way. A clicker, or ratcheting, one-way system doesn't use bearings; instead, it has a spring that pushes on toothed plates. The teeth on these plates are directional, meaning they can skip rather easily in one direction (as long as the spring tension that holds them together isn't too great), but they lock firmly in the other direction. Adjusting the tension of the spring that holds the toothed plates together allows the amount of "freewheeling" to be adjusted and even locked out completely. Set the spring loosely, and the teeth will slip easily to allow a one-way action; tighten it, and it's increasingly difficult for the teeth to slip against one another, thus limiting the one-way action.

* Adjustable one-way. Like the "clicker" one-way, this setup allows freewheeling action to be adjusted or locked out. It works like a miniature slipper clutch. A center one-way unit is usually fitted with a spring-loaded friction plate or plates that can be adjusted to limit one-way action when decelerating or braking. Set it loosely, and the front drive system spins freely; tightening it decreases the freedom with which it spins, and that increases front braking.

UPS AND DOWNS OF INSTALLING A ONE-WAY BEARING

By installing a one-way bearing, you change a car's driving characteristics. There are conditions for which one-way systems are very beneficial. These conditions are narrowly defined and oddly contrary to what most of us would assume to be the "ideal" conditions, so I'll explain how each type of unit affects a car.

* Front differential one-way. This has the most dramatic effect on handling. These are generally best for high-bite surfaces with sweeping, high-speed turns. When entering a corner off throttle, the front drive spins freely and isn't affected by deceleration or braking. Under these conditions, the front tires have exceptional bite, and this results in maximum off-power steering. Conversely, only the rear tires are used for braking, thus reducing rear bite. These conditions, without the proper chassis setup and tire combination, could result in excessive off-power oversteer. The rear-wheel-only braking is what makes this type of one-way best suited to high-bite tracks. The car would simply take too long to slow down, or it would be too difficult to control on a low- to medium-bite track. It's something like yanking the parking brake on a full-size car; it doesn't slow the car really quickly, and its rear end wiggles all over the place. This is also why front one-ways are better suited to tracks that allow cars to carry higher speeds through the corners where rear-wheel-only braking is sufficient to scrub off enough speed to make the corner. The car can be driven with more of a rolling motion�coasting through the corners and smoothly accelerating on to the straights more like a pan car. Conversely, tracks with 2x4 barriers outlining a series of tight, low-speed corners require very hard braking to haul the car down to a safe cornering speed�not a strong point of a one-way system.

Under acceleration, a front one-way eliminates differential action. In a perfect world in which all the tires are perfectly stuck to the racing surface, this wouldn't have much of an effect on handling. What's more common, however, especially in high-speed turns, is that the diffs will unload in the direction of the inside tires and this bleeds off power that could be used for better drive out of the corners. A front one-way locks under power and delivers 100 percent of the power to the ground.

* Center layshaft one-way. A center one-way is similar in function to a front one-way, but there's a very distinct difference between them: there's still a traditional front diff in the car. The center one-way allows the front wheels to freewheel when they want to spin faster than the rears, so it still eliminates front braking, and it's also better for high-bite tracks. The presence of a front diff, however, makes the center one-way somewhat of a compromise between having no one-ways at all and the aforementioned front one-way configuration. In some ways, the center one-way is better for tighter turning and low-bite surfaces than a front one-way. The front diff scrubs a little more off-power speed during corner entry, so it makes the car more manageable in slower corners. It also allows "true" differential action when exiting the corners�exactly like a car without any one-ways.

* Clicker and pressure-plate units. Clickers and pressure plates are designed to limit the action in a center one-way configuration. Tightening these units limits or eliminates one-way action for better braking, and that's best for tracks with sharp, low-speed corners that require radical acceleration and braking. Loosening the clicker or pressure-plate units allows the one-way mechanism and, subsequently, the front drive system, to freewheel under deceleration and braking, and that's better for more open tracks on which faster cornering is possible. These are the most versatile systems because they can be adjusted to suit varying track conditions.

An important note about one-ways and foam tires on touring cars: a one-way system should always be installed on a car that runs foam tires. They wear unevenly, and that makes the wheels rotate at slightly different speeds, even when the car is going straight. Unless there is a mechanism such as a one-way system to compensate for this, the drive train will bind, and this will worsen as the tires wear. The binding won't cause any immediate damage or significantly reduce performance. If you're reading this article, however, you probably race and want to get the most from your car. The subtle binding caused by running uneven foam tires without a one-way system could be enough to cost you the victory in a Main.

WRAP-UP

Now that you understand what a one-way bearing is and how it works, you'll be able to determine whether you need one. If you do decide to try one, keep in mind that you will have to change your driving style. Driving a car with a one-way requires a smoother, more flowing line rather than the choppy throttle/brake extremes used on tighter tracks. Given the right track conditions and the proper adjustments to driving style, however, a car that has been properly set up with a one-way drive system will be very tough to beat!